ULTRAAUTOSONIC innovates the Ultrasonic Sewing machine , which does not require sewing thread or other supplies, is four times faster than ordinary sewing machines and 10 times faster than glueing. Ultrasonic sewing machine uses high-frequency vibration to bond two or more layers of materials together. If two different fabrics are bonded together, the two materials should have the same melting temperature and sewing requirements.

Nonwovens, thermoplastic woven fabrics, elastic fabrics or knitted materials are ideal for ultrasonic cutting and sewing, including polyacrylonitrile, polyester, polyamide, polyethene, polypropylene, certain polyvinyl chloride, polyurethane elastic fibres and acetate fibres. The ultrasonic vibration is transmitted from the horn to the material. Frictional heat is developed where they touch. This momentary heat and pressure from the roller uses the edges of the fabric and plies join together. A cutting edge is used on the anvil to cut and seal the edges.

✔ ULTRA-USM 1 20-1000

✔ ULTRA-USM 2 20-1500

| Machine Type | USM-1 | USM-2 | ||

|---|---|---|---|---|

| Frequency (kHz) | 20 kHz | |||

| Power (Watt) | 1000 Watt | 1500 Watt | ||

| Actual Weight | Approx. 80 kg | Approx. 95 kg | ||

| Actual Size (L x W x H) | Approx. (1193 X 605 X 1267) mm | |||

| Packaging Type and Size | Wooden Box and Approx. Size (1340 X 752 X 1414) mm | |||

| Operational Requirement | ||||

| Input Power Supply | AC 230V 50/60Hz, 16Amp | |||

| CVT / Stabilizers | If the voltage is unstable then use CVT/Stabilizer to avoid damage | |||

| Working Pressure | 2 to 6 bars (Air Compressor required 1Hp 50Ltr) | |||

❑ Greatly improving work efficiency.

❑ Various patterns are available for trim, lacing and embossing on different fabrics.

❑ The power is adjustable according to the material and thickness.

❑ Moulds are easy to change, and a variety of patterns can be changed according to customer’s preferences.

❑ Compatible with Different Pattern Stitching Rollers.

❑ Customizable Cutting Parameters.

❑ High productivity and no smoke or fumes produced.

❑ Easy to operate.

❑ High accuracy.

❑ Pressure regulation.

❑ Speed control.

❑ Low noise level.

❑ Ultrasonic welded seam is more fine and neat.

❑ Time Duration.

❑ Ultrasonic Sewing machine takes less time and increases production.

❑ Low Energy consumption.

❑ Low Maintenance.

Ultrasonic Sewing Machine Application

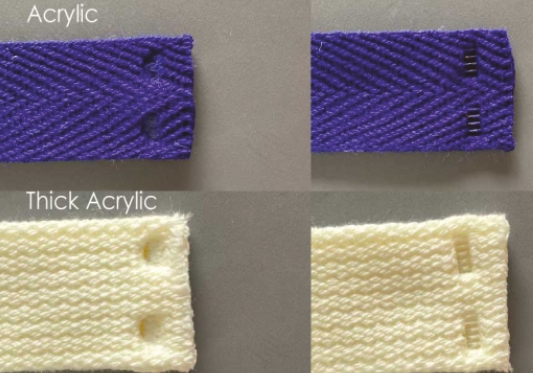

❑ Acrylic

❑ Gloves

❑ Jacket Fabric

❑ Lace Fabric

❑ Non-woven Geotextile

❑ Protective Clothing

❑ Surgical Gown

Automotive Industry

❑ Door Panel

❑ Gear Knob

❑ Inner Door Handle Cover

❑ Sitting Component

❑ Watch Belt

Home Textile Industry

❑ Coffee Bag & Table Softener Sheet

❑ Crop Fruit Cover

❑ Cushions Cover

❑ Ironing Board pad

❑ Non-woven Bag

❑ Pillow Covers & Curtains

❑ Sports & Home Apparel

❑ Table Cloth

❑ Tea Bag

Medical Textile Industry

❑ Coban Dressing

❑ Hand-gloves

❑ Mask

❑ Non-woven Crop

❑ Non-woven Wipes

❑ Surgical Cap

❑ Surgical Gown

Packaging Industry

❑ Cosmetic Pouches

❑ Food Grain Bag

❑ Metallic Pouches

❑ Non-woven Bag

❑ PP Woven Bag

❑ Standing Pouches

❑ Zip Lock Pouches

Technical Textile Industry

❑ Aeroplan Textile

❑ Bullet Proof Jacket

❑ Home Textile

❑ Medical Textile

❑ Protective Textile

❑ Raincoat

❑ Sports

Acrylic

Gloves

Jacket Fabric

Lace Fabric

Non-woven Geotextile

Protective Clothing

Surgical Gown

Door Panel

Gear Knob

Inner Door Handle Cover

Sitting Component

Watch Belt

Coffee Bag & Table Softener Sheet

Crop Fruit Cover

Cushions Cover

Ironing Board pad

Non-woven Bag

Pillow Covers & Curtains

Sports & Home Apparel

Table Cloth

Tea Bag

Coban Dressing

Hand-gloves

Mask

Non-woven Crop

Non-woven Wipes

Surgical Gown

Cosmetic Pouches

Food Grain Bag

Metallic Pouches

Non-woven Bag

PP Woven Bag

Standing Pouches

Zip Lock Pouches

Aeroplan Textile

Bullet Proof Jacket

Home Textile

Medical Textile

Protective Textile

Raincoat

Sports