Circular

Square

Triangle

Roll

ULTRAAUTOSONIC provides an innovative ultrasonic food-cutting technology: it ensures productivity gains and the optimal quality of food slicing. Ultrasonic cutting is particularly suitable for soft, frozen or fresh food products such as cheeses, meats, cold meats, pastries, pastries, etc. It is also suitable for all shapes and sizes: plates, pieces, strips, layers, rounds, blocks, bread and more. Ultrasonic mechanical vibrations have a frequency above the hearing range of the human ear. These pressure waves are produced by a generator.

In an acoustic assembly, the generator converts the electrical frequency of the network into high-frequency electrical energy. The booster, or amplitude amplifier, is used to increase or reduce the amplitude produced by the converter. It transmits the energy to the last element of the acoustic chain: the horn.The horn, a titanium-slicing blade, vibrates at high frequency. These vibrations create perfect slicing.

✔ ULTRA FC 20-1000

✔ ULTRA FC 20-1200

✔ ULTRA FC 20-1500

✔ ULTRA FC 20-1800

✔ ULTRA FC 20-2000

✔ ULTRA FC 40-500

| Frequency (kHz) | 20 | 40 | ||

|---|---|---|---|---|

| Power (Watt) | 1000/1200/1500/1800/2000 | 500 | ||

| Cutter / Blade Size (mm) | 100, 140, 170, 205, 305 mm | 85 mm | ||

| Actual Weight | Approx. 22 kg | |||

| Actual Size (L x W x H) | Approx. (483 X 458 X 238) mm | |||

| Packaging Type and Size | Corrugated Box and Approx. Size (581 X 556 X 336) mm | |||

| Operational Requirement | ||||

| Input Power Supply | AC 230V 50/60Hz, 16Amp | |||

| CVT / Stabilizers | If the voltage is unstable then use CVT/Stabilizer to avoid damage | |||

❑ No Smearing While slicing, conventional cutting methods often apply pressure directly to the food items which leads to smearing of the food products.

❑ No Shattering In case of an ultrasonic cutter, the cutting motion is so swift that it eliminates any chances of shattering the food item.

❑ High Speed An ultrasonic cutter can automatically cut through the food items at a very high speed, which you can set through your material handling equipment.

❑ Automatic tracking, real-time tracking of the frequency of ultrasonic cutting blade.

❑ Remote access capability.

❑ Independent development of a multiaxis control system.

❑ Servo motor - multi-stage variable speed, adjustable cutting speed.

❑ Infrared sensor protection device to protect the safety of operators.

❑ Ensures product integrity.

❑ Excellent Cut Face.

❑ Product does not stick to the cutting tool.

❑ High-frequency vibrations.

❑ Long blade life.

❑ Stainless steel or titanium sonotrode.

❑ Reduction of cleaning time.

Food Cutting Application List

❑ Cream Donut

❑ Bread

❑ Cake

❑ Pastry

❑ Snoflake Cookies

Dairy Products

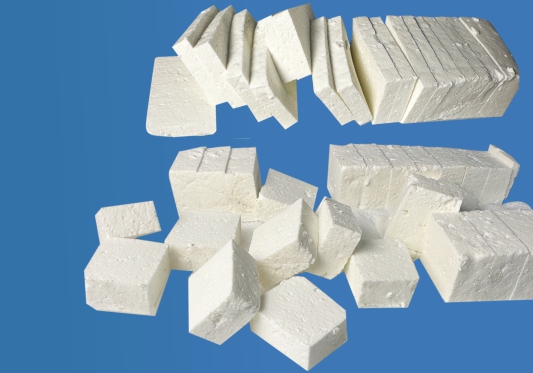

❑ Cheeze

❑ Paneer

❑ Kharwas

Confectionery Items

❑ Chocolate-Fudge-With-Nuts

❑ Swiss Roll

❑ Chocolate Bar

❑ Candy

❑ Toffee

❑ Peanut Chocolate

Frozen Food

❑ Marshmallow

❑ Ice-Cream Sandwich

❑ Meat

❑ Ice-Cream

Snacks

❑ Bhakarwadi

❑ Dhokla

❑ Maswadi

❑ Mini Sandwich

❑ Sandwich Wrap

❑ Sushi Roll

❑ Pizza

❑ Sandwich

Sweets

❑ Kaju Katli

❑ Mysore Pak

❑ Malai Sweet

❑ Rice Bar

Cream Donut

Bread

Cake

Pastry

Cake Roll

Snowflake Cookies

Cheese

Paneer

Kharvas

Chocolate Fudge With Nuts

Swiss Roll

Chocolate Bar

Chocolate Bar

Candy

Toffee

Peanut Chocolate

Marshmallow

Ice Cream Sandwich

Meat

Bhakarwadi

Dhokla

Maswadi

Mini Sandwich

Sandwich Wrap

Sushi Roll

Pizza

Sandwich

Kaju Katali

Maysor Pak

Malai Barfi

Rice Bar

Rice Bar

Rice Bar