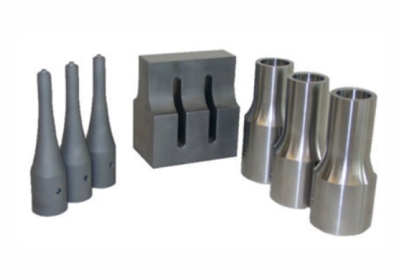

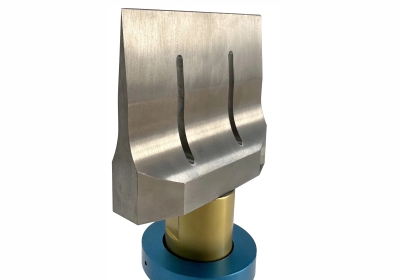

ULTRAAUTOSONIC innovates the ultrasonic horn, a sonotrode, which is a key component in ultrasonic welding and other ultrasonic applications. It is designed to transmit ultrasonic vibrations from a transducer to a material, facilitating various processes such as welding, cutting, cleaning, and more. The horn amplifies and focuses the ultrasonic energy into the desired material area, ensuring the effective application of the ultrasonic waves.

✔ Typically made from titanium, aluminium, or steel.

✔ Common shapes include stepped, exponential, and catenoidal, each designed for specific applications.

✔ Amplitude can be adjusted by changing the horn design or through mechanical adjustments.

✔ Designed to operate at specific ultrasonic frequencies, usually between 20 kHz and 70 kHz.

✔ Precision: Enables highly precise operations with minimal thermal distortion.

✔ Efficiency: Fast processing times and low energy consumption.

✔ Versatility: Applicable across various industries and materials.

✔ Cleanliness: Non-contact and clean process, reducing contamination

✔ Ultrasonic Welding: Joining of thermoplastics or metals by applying ultrasonic vibrations. The horn concentrates the energy at the joint, causing localized heating and melting.

✔ Cutting: Precise cutting of materials like food, textiles, and composites with minimal force, reducing wear on tools and ensuring clean edges.