Ultrasonic metal welding is employed in the assembly of battery packs for electronic devices, electric vehicles, and renewable energy storage systems, ensuring efficient electrical connections between battery cells and terminals.

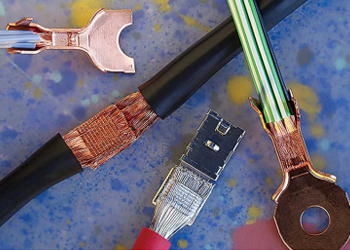

In the automotive wiring harness manufacturing process, ultrasonic metal welding is applied to splice and weld wires together, creating secure and durable connections within the electrical system.

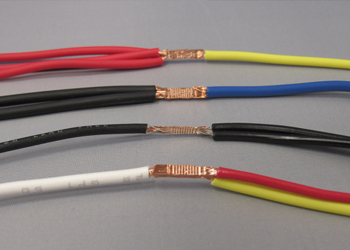

In the manufacturing of electrical cables and wires, ultrasonic metal welding is applied for splicing and welding conductive wires together, creating robust and durable connections.

Ultrasonic metal welding is used to join extremely thin wires, down to a few micrometers in diameter, used in microelectronic devices.

Ultrasonic metal welding is commonly used to join the tabs of automotive batteries. Battery tabs are the metal strips that connect individual battery cells, and it is crucial to create strong and low-resistance connections to ensure the overall efficiency and performance of the battery pack.

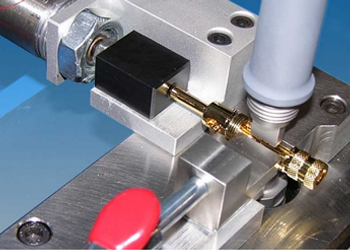

Metal bonding with ultrasonic metal welding is a solid-state welding process that utilizes high-frequency ultrasonic vibrations to create strong and reliable bonds between metal components.